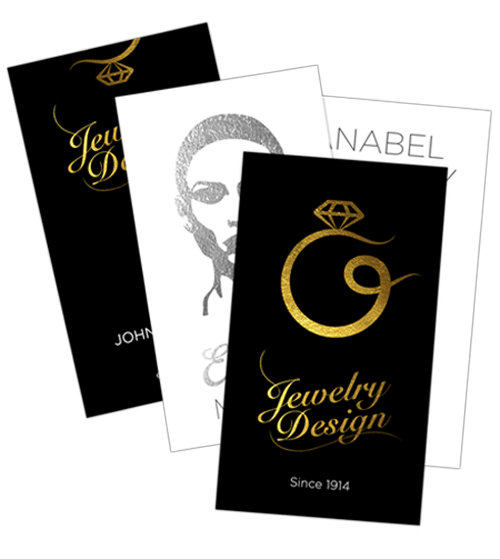

Foil Worx

Let’s say you decide to go very stylish and elegant. And let’s suppose you like gold, silver

or even better rainbow. After we did the math, the conclusion is Foil Worx.

- Cardstock: superior quality stocks.

- Basic: gold, silver, copper and so many other foil accents.

- Custom made: single or double sided, rounded corners, perforation

Foil Worx stamping consists in transferring a film or aluminum foil onto paper using heat and pressure. A wide variety of foils are available outside of gold or silver: pigmented colors, iridescent, pearlescent, holographic, and colored gloss or satin metallic foils, based on aluminum foils with lacquer.

There are many considering a touch of gold or silver will make it more elegant and unique. Consider it the key of your success if want to go elegant-Hot Foil

Uses and Ideas

- Business cards

- Packaging and label markets

- Invitation cards

- Postcards

- Holiday cards

Foil Worx stamping consists in transferring a film or aluminum foil onto paper using heat and pressure. A wide variety of foils are available outside of gold or silver: pigmented colors, iridescent, pearlescent, holographic, and colored gloss or satin metallic foils, based on aluminum foils with lacquer.

It may look the only difference between hot foil and cold foil printing is the temperature but there’s more to it.

Besides the heat application, there ’s a difference in the process, and the end effect. Read this article to understand the difference and to help you decide between foil stamping and foil printing for your packaging.

The Process

Foil Worx uses a dye with a relief image. The heated die presses, or stamps, the foil onto paper, plastic or other material creating a brilliant, eye-catching effect. Foil stamping is done on a second line, meaning that your packaging will be printed first, then placed on another press for stamping.

Some customers like to add embossing to foil stamping. These two finishes can be completed at the same time and don’t require a third pass.

The result of foil stamping is a brilliant and what you would expect when you think of foil. It’s readily available in a wide range of colors and patterns such as such as holographic, pigmented and clear foil which are not available with the cold foil process.

Also, since the foil is stamped on, there is a slight debossed effect characteristic of “high quality.”

Foil Worx stamping works great for precise application, on smaller areas, and for creating an upscale look as the stamping process makes a slight impression that gives depth. It also hints at a hand-crafted look, which may not be too far from the truth as some jobs may require the use of a hand-fed press for foil stamping.

Dos

do use papers from 160g for double-sided hot foil stamping applications.

do make the most of smoother papers, such as Conqueror CX22 or Opal Premier, for mirror finish foiling. Despite the pressure applied during the foiling process, the texture of the paper will show through the foil.

print with offset lithography or screen printing before going through with the hot foil stamping process.

ensure the films are suitable for subsequent laser use when foil-stamping letterheads.

think in terms of creative contrast: for instance foil worx stamping gold or silver foils works well on dark Curious Collection Skin papers.

do check when using metallic foil on black paper. The foil could react with the carbon dyes present in some papers. Conqueror Calligraphy, Keaykolour Deep Black, Pop’Set Black and Extra Black and Rives Tradition Le Noir, for example, are safe: they do not contain any carbon black.

Don’ts

don’t use papers with low bulk or rigidity. The foil worx stamping process could crumple or tear the sheet.

don’t pick heavily textured papers for foiling images which contain very fine detail (such as a royal crest for example), unless you consider plate-sinking the area to be foiled first.

don’t use clear foil on colored Curious Collection Skin papers. Use UV varnish instead.

don’t choose magnesium plates for heavily structured or textured papers, as they will become blunt and lose detail quite quickly. Copper plates, although more expensive, will render a finer job.

don’t forget hot stamping is a craft, where much depends on the special know-how and skill of the printer.

What we offer

If all that we’ve said seems too complicated, don’t hesitate to ask for our Design to Print service. Our knowledgeable designers will do whatever it takes to create what you need.

Cardstock:

- 14 pt Uncoated

- 16 pt C2S

Basic options:

- sizes raging from 1.5 x 3.5 to 5 x 7

Custom made:

- silk laminated

- custom die cut

- color edging

- variable data

- spot uv or raised uv

- embossing

- scratch off

- round corners

This being said we are waiting for you to visit us on bwprintingservices.com or to call us at 818-966-0816 and to order the most unique Foil Worx.

Reviews

There are no reviews yet.